FORGE is an EC research project considering issues associated with the generation, migration and fate of gases generated in radioactive waste disposal facilities.

The Radioactive Waste Management Directorate (RWMD) of the UK Nuclear Decommissioning Authority (NDA) is participating in this project, and Quintessa is providing technical support to RWMD under Work Package 1 (Treatment of Gas in Performance Assessment). This work package is focussed on the complex issue of understanding how to characterise and represent gas migration a in manner suitable to support whole facility performance assessments.

To date Quintessa has been using the QPAC code to participate in benchmarking, sensitivity and upscaling activities looking at the behaviour of generated gas (along with water, water vapour and dissolved gas) during the resaturation of a spent-fuel (SF) facility in an argillite host rock. Other organisations - including ANDRA, ENSI, IRSN, SCK-CEN and LEI - are using other software in their input to the project. The benchmarks have examined:

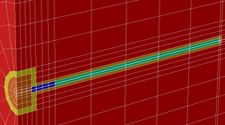

- a single SF disposal cell considering waste, engineered disturbed zone, bentonite plug, backfill and explicit representation of potential interface structures between the different materials ('cell' scale) and, more challengingly,

- a 'module' scale benchmark in which 100 of the disposal cells are modelled explicitly including all of the features in the smaller scale benchmark in addition to the larger drifts.

A whole repository benchmark model is also planned, and it is expected that understanding gained in how process and property upscaling is best handled at the 'cell' and 'module' scale will be applied to this larger scale model.

The results have demonstrated the importance of understanding the role of interface structures. Different representations of these features using conventional approaches can be both numerically challenging and exhibit strong control on the system evolution. Having overcome the initial numerical challenges, innovative prototype models of dilatant effects associated with some interface structures have been demonstrated by Quintessa using upscaled hydro-mechanical process models.

Over the remaining period of the FORGE project (which concludes in spring 2013), it is anticipated that input from other work packages dealing with the experimental behaviour of material interfaces will be used to inform upscaled hydro-mechanical representations, to give a more appropriate, physically based, representation of gas migration at all scales of interest, up to and including the whole-facility scale. Ultimately this work will inform understanding and predictive modelling of future disposal facility performance.